With the rapid development of electric vehicles in China, many countries in the world have purchased Chinese electric vehicles. However, the battery charging technology of some Chinese electric vehicle brands uses super-fast charging technology, and some users recommend that super-fast charging should not be used frequently. In the face of this concern, we will combine the impact of super-fast charging of electric vehicles on batteries, and conduct a comprehensive analysis based on the original technology and actual cases.

Super-fast charging technology principle

Super-fast charging uses direct current to directly inject into the battery pack, and realizes rapid input of electrical energy through high voltage (400-800V) and high current (300-500A). Its essence is to complete rapid energy replenishment by shortening the time for lithium ions to migrate from the positive electrode (such as NMC ternary materials) to the negative electrode (graphite or silicon-based materials).

The chemical nature of battery charging

When charging lithium-ion batteries, lithium ions need to be deintercalated from the positive electrode, pass through the electrolyte and diaphragm, and embed into the negative electrode material. Fast charging causes lithium ions to migrate too fast, which may cause the following problems:

Negative electrode lithium precipitation: lithium ions are not fully embedded in the negative electrode under high current, and are deposited in the form of metallic lithium, forming lithium dendrites;

Electrolyte decomposition: high temperature accelerates the oxidation and decomposition of the electrolyte, generating gas and thickening the solid electrolyte interface film (SEI film);

Structural stress: rapid lithium ion insertion/extraction causes the volume expansion and contraction of the electrode material to intensify, causing microcracks.

Battery life decay

Fast charging will reduce the number of battery cycles. Laboratory data show that frequent fast charging (more than 3 times a week) may shorten the battery cycle life by 20%-30%, mainly due to high temperature accelerated side reactions and irreversible thickening of the SEI film.

Capacity loss

A case analysis of a certain brand shows that the battery capacity of vehicles that frequently use fast charging in two years has an average decay of 15% (compared with 8% of slow charging vehicles). This is directly related to the rupture of the negative electrode semipermeable membrane and the loss of active substances.

Thermal management challenges

Tesla V3 supercharge test shows that the battery pack temperature can reach above 45°C during fast charging (slow charging is usually ≤35°C). Long-term high temperature will accelerate the volatilization of electrolyte and the collapse of electrode material lattice, causing capacity to drop.

Material layer damage

Negative electrode graphite layer peeling : High current causes uneven lithium ion embedding and stratification of graphite layer structure;

Positive electrode metal dissolution : Metal ions such as nickel, cobalt and manganese dissolve under high voltage, destroying electrode stability.

CATL experimental data

The NCM811 battery was tested for 1.5C (about 30 minutes to charge to 80%) fast charging cycle. After 800 cycles, the capacity retention rate was only 78%, while the 0.5C slow charging group retention rate reached 92%.

User scenario survey

According to statistics from a well-known Chinese automobile operation platform (average daily fast charging 2 times), the capacity decay of the battery of an operating vehicle generally exceeds 25% in 3 years, which is significantly higher than the 12% of private cars (average annual fast charging <50 times).

Priority strategy

Daily charging is mainly slow charging (recommended fast charging ≤1 time per week);

Avoid starting fast charging when the battery temperature is >40℃.

Charging habit optimization

Switch to slow charging after fast charging to 80% to reduce the terminal high-voltage charging pressure;

After long-distance driving, let it cool for 30 minutes before charging.

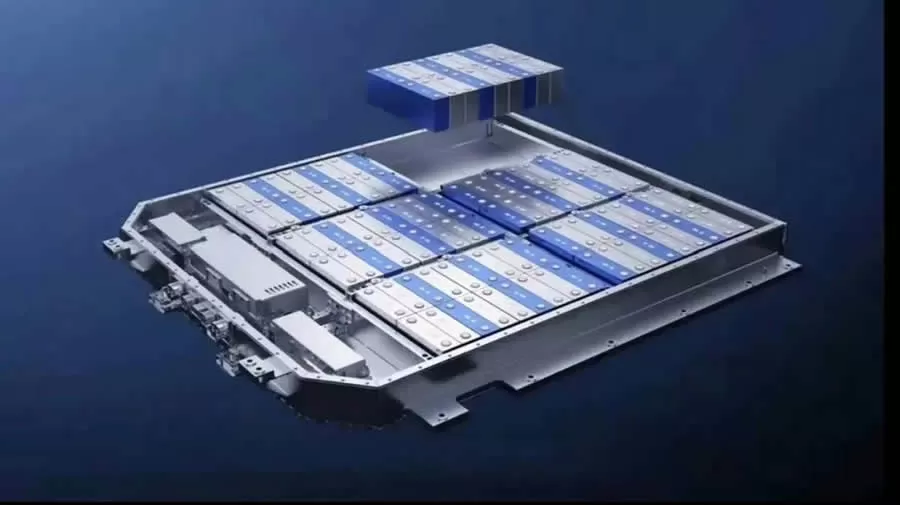

Technical compensation measures

The new generation of batteries (such as CATL Kirin batteries and BYD blade batteries) can reduce the fast charging decay rate to less than 3% per year through three-dimensional cooling and flexible electrode design.

Combined with the analysis of the frequent use of super-fast charging in electric vehicles, we have learned that super-fast charging does have a significant negative impact on battery life and performance, but it can be effectively alleviated through reasonable use strategies and new battery technologies. It is recommended that users balance charging efficiency and battery health according to actual needs.